What’s a better protection option – a ceramic coating or a wax? Speak to most detailers, and their response when asked is:

‘Ceramic is always WAY better than wax’.

And here begins the problem…

Better AT what?

Better FOR what?

Ceramic coatings have many outstanding attributes as a paint protection product, but they also carry some inherent problems. Likewise, waxes have some negative attributes but also do some things extremely well. When choosing a product for our own vehicles the decision is relatively easy as we know what we want from it!

Ceramic coatings have many outstanding attributes as a paint protection product, but they also carry some inherent problems. Likewise, waxes have some negative attributes but also do some things extremely well. When choosing a product for our own vehicles the decision is relatively easy as we know what we want from it!

When dealing with customers on a regular basis, we actually need to work quite hard before the detailing even starts, to ensure that we are offering the best possible service we can, and to maintain a relationship with returning customers.

As mentioned earlier, ceramic coatings have some amazing attributes. Below we have compiled a list of them, and given some explanation as to why they work this way.

Scratch resistance

Not to be confused with scratch-proof, ceramic coatings offer a hard glass-like layer which is in certain cases harder than the original paint finish. This information is key, as the coating will only reach a hardness level in relation to the original hardness of the paintwork. Imagine it as applying as a sheet of cling film over a mattress, or a sheet of cling film over concrete. The hardness rating usually plastered all over the marketing material can be very misleading. 9H, 9H+, and 10H all sound incredibly hard and exactly what we want. Apart from two vital problems, 9H Mohs and 9H pencil test ratings are entirely different, and the testing carried out to fetch this data is carried out on a metal substrate – not paint.

Ceramic coatings will reduce the number of scratches over a period, but will not prevent them entirely.

Hydrophobicity

Beads!!! What every customer wants, and the only true way to show that a car is protected! Nope…

Believe it or not, the best coatings for ease of cleaning are actually hydrophilic. Hydrophobic is cool because you get beads, water runs off and you can do cool Insta-posts when it rains. There is some science behind the beading properties of ceramics, but the hardest and longest-lasting elements of ceramic coatings are often only semi-hydrophobic (or semi-hydrophilic, in a glass half-full kinda way).

Gloss

Ceramics are often seen as giving massively improved levels of gloss, especially when depicted in ‘before and after’ pictures. The sad reality is that a lot of cheaper ceramic coatings actually show a decrease in gloss levels when compared to perfected paintwork. The majority of gloss improvement takes place within the paint correction process, not after ceramic application.

Easy aftercare

Ceramic coatings are relatively low maintenance in most circumstances, with only regular washing with pH-neutral shampoo and occasional application of QD to keep them at their best. Unfortunately, there are also pitfalls in ceramic coating maintenance, with specialist products required if they become blocked, and full removal and reapplication being necessary if they fail (more on this later).

So what about waxes then?

By the sounds of it… “WAX IS DEAD” – at least pretty irrelevant to modern detailers

Not quite…

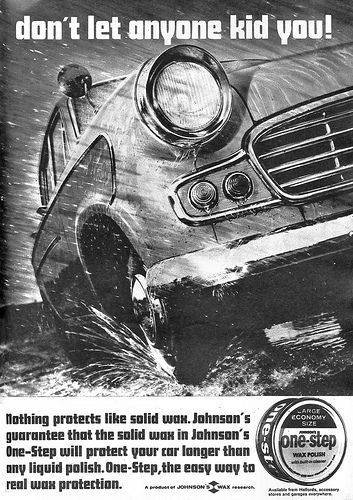

Wax is often seen as the ‘romantic’ way to protect a car these days, with detailers opting for hi-tech SiO2 ceramic-type coatings for everything. The issue here is that most are oblivious to how destructive ceramic coatings are in the long run. Ceramic coatings work by forming a molecular bond with the surface of the paintwork. This takes place when molecules in the coating form covalent bonds with molecules in the clear coat on the vehicle. Basically, they merge together to form a permanent bond.

This is awesome for lifespan, resistance to chemicals and scratch resistance, but what happens when it does get scratched, or we need to remove it entirely to apply a new coating – perhaps when approaching the end of life?

The only way to fully remove a cured ceramic coating is to use abrasion. There have been some YouTubers claiming that certain maintenance products will ‘strip’ ceramic coatings, but it is pure nonsense.

Once cured, you need to mechanically remove the coating with polishing or (rarely) sanding. The problem with this is that we will need to remove an amount of the original clear-coat every time this is carried out (due to the molecular ‘merging’. Now consider that most detailers recommend a top-up or new application every 2-3 years, it would lead to a 15-year-old car having been machine polished (heavily) 4 or 5 times already. In trying to protect the paintwork with ceramic coatings, we are actually destroying it a little, each time we carry out the service on the car.

Wax can be applied regularly and stripped entirely from a vehicle with careful use of non-abrasive products. This makes it much more preferable for vehicles, where the original paint is way more valuable than having a protection product which lasts a couple of years. The best example of this would be classic vehicles.

There is another aspect that often gets overlooked, and that is the weekend habits of the customer…

Most customers will return to you for maintenance, which is great. You get to earn more money, and also keep tabs on the protection package you carried out. However, there are millions of vehicle owners out there, that enjoy cleaning their own cars at the weekend. Ceramic coatings are often ideal for this, but not if the customer enjoys waxing their vehicle every 4 weeks. Despite the influx of quick detailer products, certain customers just love waxing their car! This can cause massive issues if they wax over a ceramic, and will leave them asking the question – ‘Why did I bother?’.

Water spotting is a known issue with ceramic coatings, and this can really put customers off, if and when it happens. It only takes a mild downpour, followed by a sunny spell, and we could be looking at a coating with severe etching. In certain cases, this can only be remedied with a full strip and reapplication. Not ideal after forking out £££’s for ‘protection’. Mineral deposits are also an issue with water spotting, but these can be remedied with water spot removers (yet another product the customer will need at home). The final worry of home-aftercare is blocked coatings. Blocked coatings give the impression of a failed coating, when in reality it is a blocking of the hydrophobic properties through mineral build-up. This is remedied with specific (and often expensive) acid-wash shampoo products designed for this purpose. Suddenly, the ‘easy aftercare’ of ceramic coatings does not look so rosy.

The last point to ponder is the magic R word that we all love in business… Revenue.

Ceramic coatings tend to be charged out at a much higher rate due to their lifespan, typically anywhere between £700 and £1500 for a paint correction and coating application. This has gently nudged a lot of the industry to ‘one-visit’ customers. They carry out an extensive detail, charge a large amount and wave goodbye to the customer. Before ceramic coatings became so popular, we would see customers returning every month, quarter or bi-annually for more protection to be added to the vehicle. The illusion was that the extra revenue from one single ceramic coating job outweighed the 3 or 4 jobs per year with other products. Sadly it is just that… an illusion.

Consider the labour involved in preparing and applying ceramic coatings. They often take longer to apply and can suffer from more issues during application than most other protection products. This is before we even mention the use of air conditioning and IR curing lamps for certain ceramic coatings.

If we look at a standard decontamination, single-stage light preparation polish, and application of a polymer/hybrid wax generating between £350 and £500 two or 3 times a year, then this would be more beneficial than just one £1500 service every 2-3 years.

There is some scope for customers to be recalled with ceramic coatings for ‘top-up’ details annually, but this almost defeats the object of selling that type of protection to the customer in the first place. The extra cost of the detail was intended to represent the vastly improved lifespan. There have been wild claims from certain manufacturers that their coating will last 7, 8 or even 9 years. The reality is that there is a strict annual service plan to be adhered to, and the particulars of the protection warranty are flimsy to say the least.

In summary, the topic of ‘Wax vs Ceramic’ is way more complex than most detailers care to imagine. It requires some good forward planning on behalf of the customer, and also assessment of both instant AND ongoing revenue. Could it be that we have been drawn to the shiny new products due to trends, and actually left behind the more profitable (and less laborious) protection products?…

©2021 UK Detailing Academy. No unauthorised reproduction of this blog is permitted in part or as a whole without author permission.